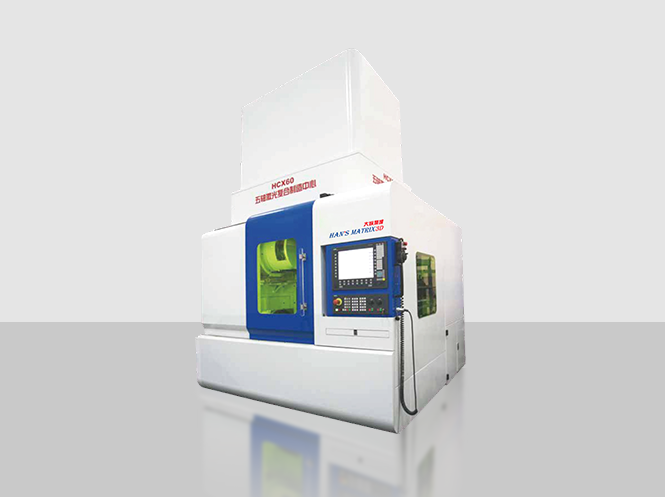

Product features:

1. Organic combination of additive manufacturing and subtractive manufacturing;

2. Can perform powder coating additive, milling, grinding and polishing composite processing;

3. Equipped with a knife magazine, automatic tool changing and melting head replacement can be achieved;

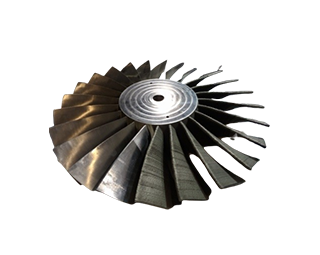

4. High precision flexible manufacturing capable of processing complex surfaces and cavities;

5. Five axis linkage, high-precision CNC system;

6. Application industries: military, aerospace, automotive, mold, engineering machinery, etc.

Equipment parameters

Working range | Φ400mm x 350mm |

Travel X-axis | 600mm |

Travel Y-axis | 500mm |

Travel Z-axis | 650mm |

X&Y&Z axis positioning accuracy | 0.01mm |

X&Y&Z axis Repeatability positioning accuracy | ±0.005mm |

Spindle speed | 18000rpm |

Number of cutting tools | 20 pieces (16 pieces optional) |

Maximum drilling diameter | Φ16mm |

Maximum boring diameter | Φ60mm |

Workbench size | Φ500mm |

Workbench load-bearing capacity | 500kg(0°)、300kg(90°) |

Control system | Siemens 840D |

Machine weight | 7000kg |

Overall dimensions | 3500mm x 2500mm x 3600mm |