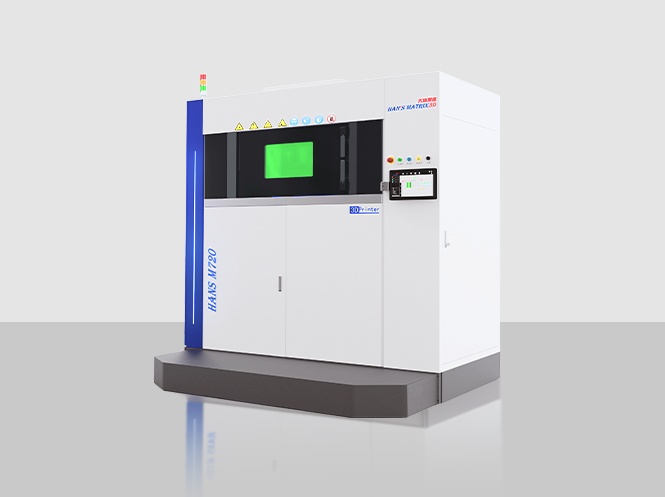

Han′s Matrix3D possesses comprehensive mold processing technologies including blank cutting dies, punching dies, compound dies, extrusion dies, four-slide dies, progressive dies, stamping dies, and die-cutting molds, which can be widely applied in the precision mold processing industry.

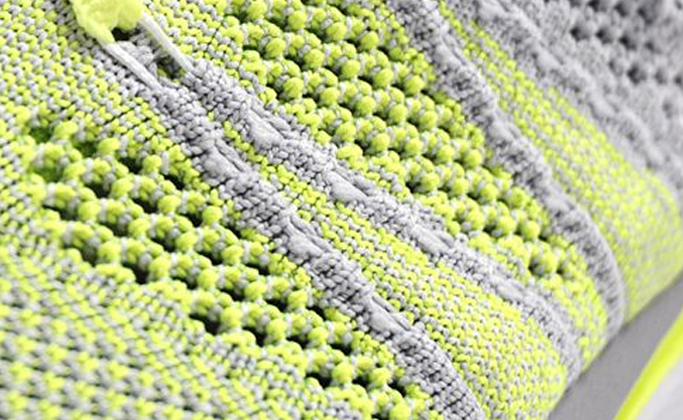

Mold processing encompasses the manufacturing of forming and blanking tools, extending to the precision fabrication of shear dies and die-cutting molds. 3D printing technology has revolutionized the field of mold processing, with its wide-ranging applications including the precise cutting of blanking dies, rapid prototyping of punch dies, complex structure construction of compound dies, high-strength design of extrusion dies, smooth operation mechanisms of four-slide dies, continuous operation optimization of progressive dies, efficient stamping of stamping dies, and accurate cutting of die-cutting molds. These processes are achieved through the layer-by-layer deposition technology of 3D printing, which not only enhances processing efficiency but also reduces costs, accelerating the speed of product development from design to market.

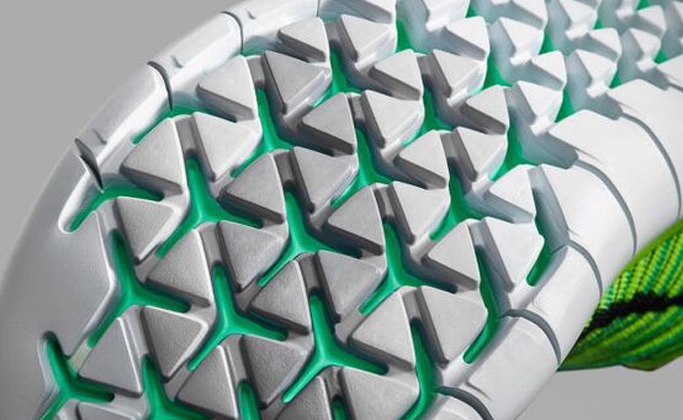

3D printed products demonstrate significant advantages in improving cooling efficiency, reducing injection mold cooling time, ensuring uniform mold temperature distribution, and overcoming traditional manufacturing limitations. The technology enables customized conformal cooling channels tailored to specific mold geometries and product requirements. This conformal cooling design allows coolant to flow closer to injection-molded products, achieving more efficient heat transfer and more uniform cooling effects.

The 3D printed conformal cooling channels ensure better temperature uniformity across molds, helping minimize product defects like warping and cracking while improving yield rates. Additionally, the technology can produce complex, precision geometric structures and internal cavities that are unachievable through conventional methods.