3D printer has been widely adopted in automotive manufacturing processes, including clutch component processing, bumper fabrication, center console panel glass production, and automated commercial vehicle wheel hub machining lines

The widespread application of 3D printing technology in automotive manufacturing has not only enhanced production efficiency and precision, but also significantly driven product innovation and personalization.

● Clutch Components: 3D printing enables direct formation of complex structures, reducing assembly steps while improving overall part performance.

● Bumpers: The technology allows rapid customization to meet evolving market demands, balancing both safety and aesthetic requirements.

● Center Console Glass: Unprecedented design possibilities are now achievable, elevating the cockpit's technological sophistication and luxury appeal.

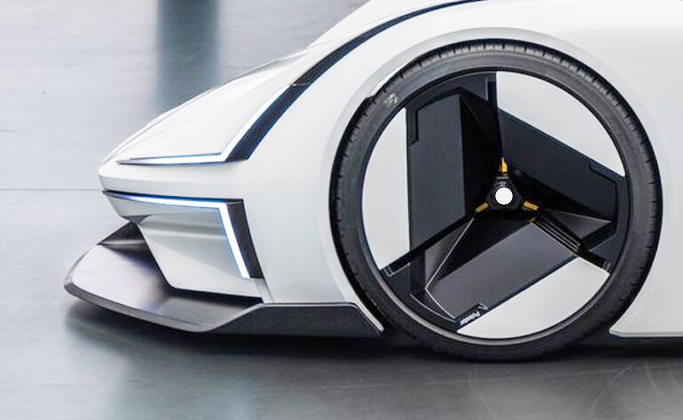

● Commercial Vehicle Wheel Hubs: Automated production lines integrated with 3D printing achieve efficient, flexible mass production, accelerating the intelligent transformation of automotive manufacturing

The application of 3D printing in NEV components is becoming a trend. Key advantages include:

● Shortening R&D cycles

● Enabling lightweight designs

● Improving ergonomics for safety/comfort

● Supporting prototyping, small batches, and customized parts

This technology allows:

● Digital-to-physical rapid prototyping

● Precise lightweight manufacturing

● Complex geometries beyond traditional limits

● Fast customization per customer needs

Lightweight materials such as aluminum alloy are commonly used in 3D-printed wheel hubs to achieve weight reduction, enhancing fuel efficiency and vehicle performance. 3D printing technology enables the production of intricate wheel hub designs, improving both functionality and aesthetics. The HANS M460 is a high-precision, multi-functional 3D printer capable of consistently producing high-quality aluminum alloy parts. With a printing time of 132 hours, it delivers exceptional stability and continuity, making it ideal for large, complex components. Meanwhile, high-strength materials like stainless steel can be precisely 3D-printed into brake plates, ensuring optimal braking performance and safety. The M260, a more compact and flexible system, is well-suited for small to medium-sized parts. With a printing time of 28 hours, it offers high efficiency when processing dense, high-melting-point materials such as stainless steel.